![]()

Researchers from the Technion – Israel Institute of Technology have developed a method of manufacturing optical components faster and cheaper for a variety of purposes, which could include camera optics.

The researchers originally published the news of their development in February, but this past month uploaded a video (spotted by DIY Photography) that shows how the method is able to produce complex and precise optical components quickly and without the need for casting or polishing.

A Novel Method for Manufacturing Lenses

The researchers say that presently, lenses need to be shaped by specialized machinery in order to form the shapes needed for different optical functions. Camera lenses, in particular, use sets of differently shaped lenses in order to correct for optical aberrations.

“Our approach to making freeform optics achieves extremely smooth surfaces and can be implemented using basic equipment that can be found in most labs,” research team leader Moran Bercovici from the Technion – Israel Institute of Technology explains. “This makes the technology very accessible, even in low resource settings.”

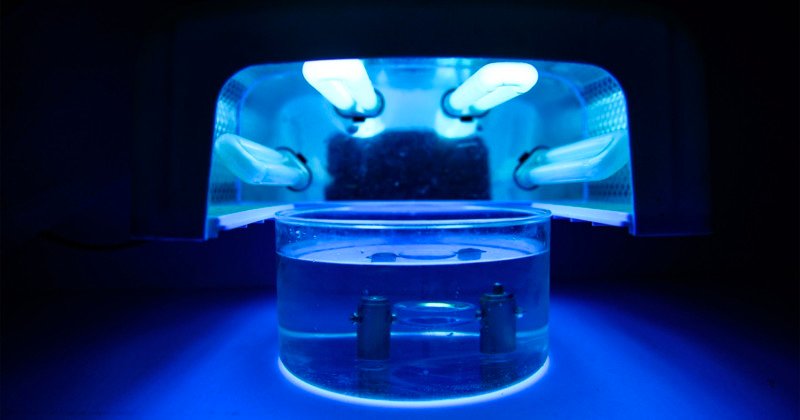

The process involves using a liquid polymer contained within a special liquid environment that is able to make complex shapes through the physical forces acting on it. Once the polymer is formed into its final shape, it is hardened using UV radiation to become a solid lens.

The team explains that one of the primary challenges in making optics by curing a liquid polymer is that for optics larger than about two millimeters, gravity dominates over surface forces, which causes the liquid to flatten into a puddle. To overcome this, the researchers developed a way to fabricate lenses using a liquid polymer that is submerged in another liquid. The buoyancy counteracts gravity, allowing surface tension to dominate.

Because they are able to remove the effects of gravity, the researchers can fabricate smooth optical surfaces by controlling the surface topography of the lens liquid.

“This entails injecting the lens liquid into a supportive frame so that the lens liquid wets the inside of the frame and then relaxes into a stable configuration,” the researchers explain. “Once the required topography is achieved, the lens liquid can be solidified by UV exposure or other methods to complete the fabrication process.”

The team was able to show they could make lenses with this method up to 200mm in size with a final product that has surface qualities similar to the best polishing techniques available, but by what they describe as an order of magnitude quicker and simpler to make.

“We identified an infinite range of possible optical topographies that can be fabricated using our approach,” Mor Elgarisi, the paper’s lead author, says. “The method can be used to make components of any size, and because liquid surfaces are naturally smooth, no polishing is required. The approach is also compatible with any liquid that can be solidified and has the advantage of not producing any waste.”

Demonstrating the Process

The video above shows the process of fabricating a lens with the new process, and the team says that they are currently working on a way to automate the fabrication so that different optical topographies can be made in a precise, repeatable way. The team is also working with different polymers to see which can make for the best optical components.

Once they achieve this, the novel method can theoretically be used to create faster prototypes than even 3D printing and even seems capable of replacing elements found in a variety of lenses.

The team has published its full research in Optica.

Image credits: Header photo shows the new lens manufacturing method in progress, Technion – Israel Institute of Technology